-11 %

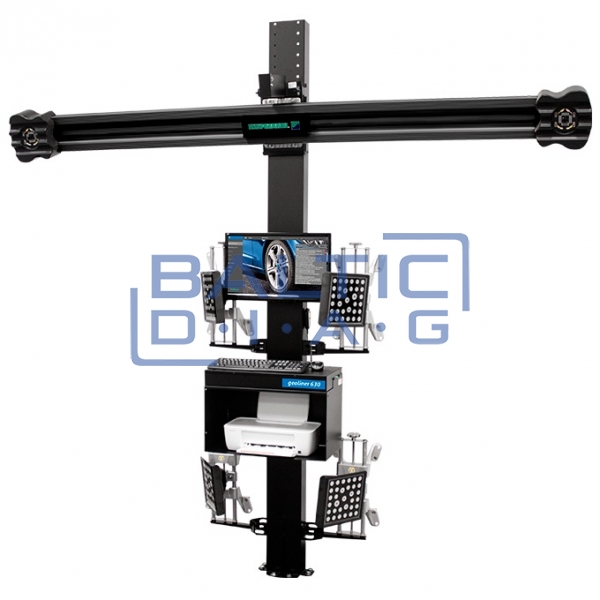

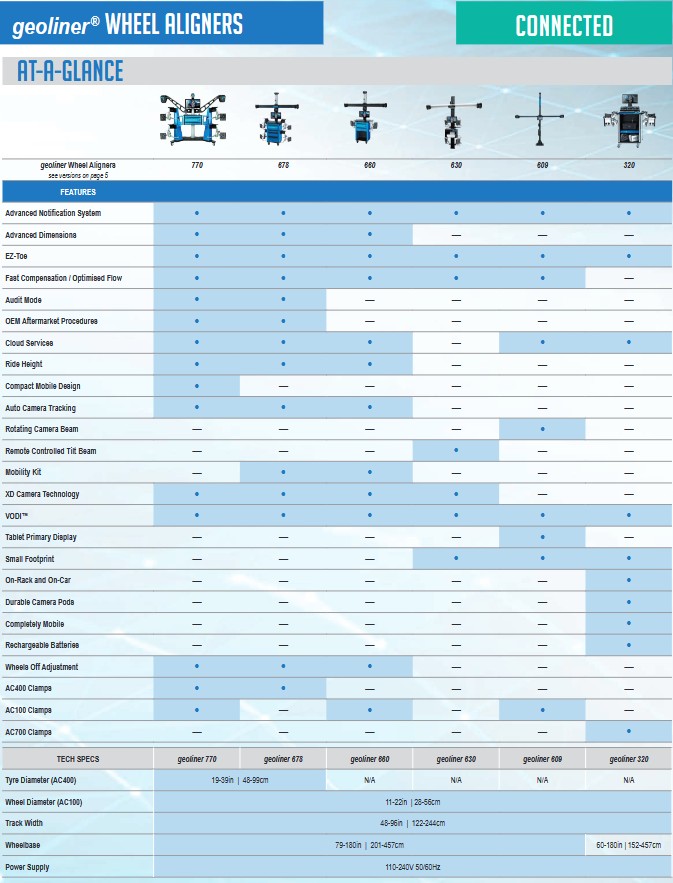

Wheel aligner geoliner® 630 Hofmann

- SKU: BD70455

13,999.00 €

15,730.00 €

,%2012-kampės-600x600.jpg)