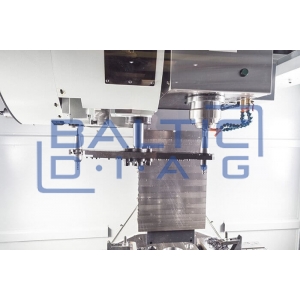

Įmonė prekiauja lengvajam, sunkiajam transportui, autobusams bei agrotechnikai skirta diagnostine bei servisų įranga.

Siūlome didžiausią kompiuterinės diagnostikos prietaisų pasirinkimą

Baltijos valstybėse. Garantuojame Jums palankiausią kokybiškų produktų

kainą.

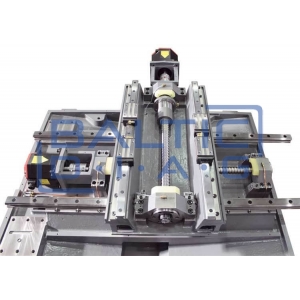

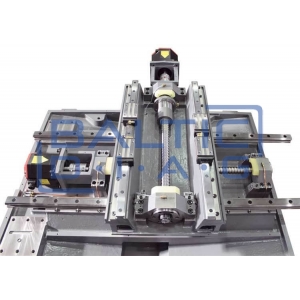

Customer system