-7 %

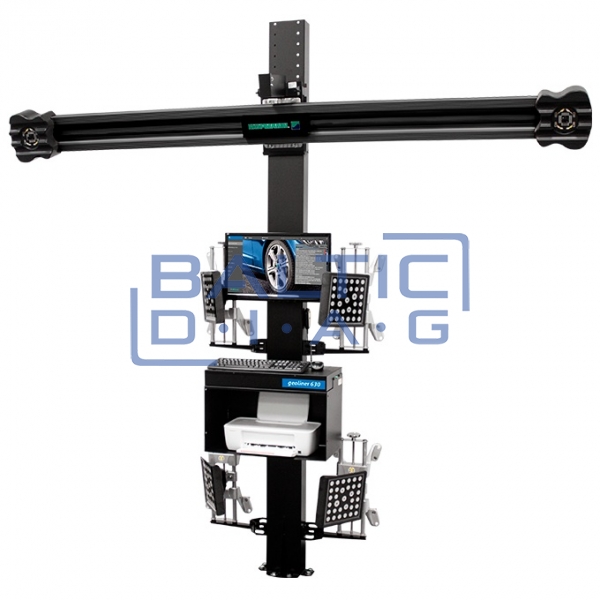

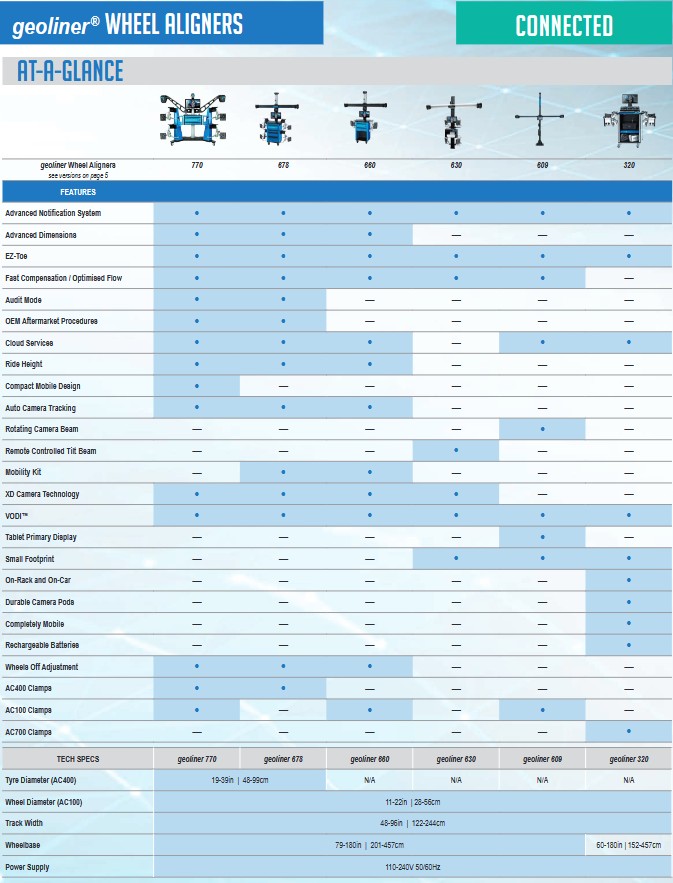

Wheel aligner geoliner® 630 Tilt Hofmann

- SKU: BD70454

14,883.00 €

15,999.00 €