-

Repair shop equipment

-

Diagnostic equipment

See all 1

Diagnostic equipment

See all 1

-

Vehicle lifts

See all 1

Vehicle lifts

See all 1

-

Wheel and tire repair equipment

See all 1

Wheel and tire repair equipment

See all 1

-

Chassis repair equipment

See all 1

Chassis repair equipment

See all 1

-

Air compressors

See all 1

Air compressors

See all 1

-

Vehicle AC filling and maintenance equipment

See all 1

Vehicle AC filling and maintenance equipment

See all 1

-

Fuel injector testing equipment

See all 1

Fuel injector testing equipment

See all 1

-

Welding equipment

See all 1

Welding equipment

See all 1

-

Brake, chassis and headlamp inspection equipment

See all 1

Brake, chassis and headlamp inspection equipment

See all 1

-

Washing and cleaning equipment

See all 1

Washing and cleaning equipment

See all 1

-

Workbenches and workshop furniture

See all 1

Workbenches and workshop furniture

See all 1

-

Vehicle repair tools

See all 1

Vehicle repair tools

See all 1

-

Other repair shop equipment

See all 1

Other repair shop equipment

See all 1

-

Electric car charging stations

See all 1

Electric car charging stations

See all 1

No subcategories. -

-

Industrial equipment

-

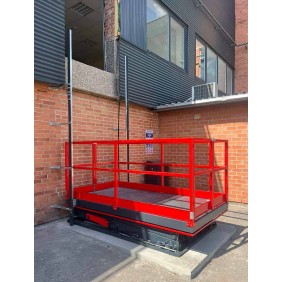

Lifts for industry

See all 1

Lifts for industry

See all 1

-

Professional warehouse equipment

See all 1

Professional warehouse equipment

See all 1

-

Sandblasting equipment

See all 1

Sandblasting equipment

See all 1

-

Painting equipment

See all 1

Painting equipment

See all 1

-

Generators

See all 1

Generators

See all 1

-

Metal processing equipment

See all 1

Metal processing equipment

See all 1

-

Woodworking equipment

See all 1

Woodworking equipment

See all 1

-

- Promotions

- Promotions

-

Repair shop equipment

-

Diagnostic equipment0

Diagnostic equipment0

- Car diagnostic equipment0

-

Diagnostics of specialized and heavy vehicles0

- Top Diagnostics of trucks and semi-trailers0

- Diagnostic equipment for agriculture and construction vehicles0

- Diagnostic equipment for bus and light commercial vehicles0

- Water transport diagnostics0

- Tachographs, Emulators, error erasing devices0

- Database and license spec. and heavy vehicle diagnostics0

- Motorcycle diagnostic equipment0

- Oscilloscopes, endoscopes and testers0

- Programming equipment0

- EV battery service equipment0

- Add-ons, updates, licenses0

-

Vehicle lifts0

Vehicle lifts0

-

Wheel and tire repair equipment0

Wheel and tire repair equipment0

- Tire changers machines0

- Wheel balancing machines0

- Tyre changer and wheel balancer sets0

- Accessories for mounting and balancing machines0

- Rim straightening machines0

- Top Wheel alignment equipment0

- Wheel washing equipment0

- Wheel spray guns0

- Tire inflation cages0

- Wheelchairs, jacks0

- Other tyre repair quipment0

- Tire racks, conveyors0

-

Chassis repair equipment0

Chassis repair equipment0

- Chassis straightening equipment0

- Top Induction body straightening tools0

- Discount Dent puller generators and dent pulling sets0

- Chassis measuring equipment0

- Automotive body riveting equipment0

- Top Infrared paint heaters0

- Dent straightening equipment0

- Chassis rotisseries0

- Hydraulic chassis straightening tools0

- Painting stands0

- Other chassis repair equipment0

- Painting tools0

-

Air compressors0

Air compressors0

-

Vehicle AC filling and maintenance equipment0

Vehicle AC filling and maintenance equipment0

-

Fuel injector testing equipment0

Fuel injector testing equipment0

-

Welding equipment0

Welding equipment0

-

Brake, chassis and headlamp inspection equipment0

Brake, chassis and headlamp inspection equipment0

-

Washing and cleaning equipment0

Washing and cleaning equipment0

-

Workbenches and workshop furniture 0

Workbenches and workshop furniture 0

-

Vehicle repair tools0

Vehicle repair tools0

- Battery chargers and starters0

- Top Tool trolleys 0

- Smoke leak detectors 0

- Waste oil collection equipment0

- Hydraulic equipment0

- Mobile platform lifts0

- Automotive and other jacks0

- Engine Stands and Lifts0

- Tools and Tool Sets0

- Pneumatic tools0

- Cordless tools0

- Electrical tools0

- Torque wrenches0

- Lifting and Pulling Winches0

- Vices0

- Axle stands0

- Work lamps0

-

Other repair shop equipment0

Other repair shop equipment0

-

Electric car charging stations0

Electric car charging stations0

-

-

Industrial equipment

-

Lifts for industry0

Lifts for industry0

-

Professional warehouse equipment0

Professional warehouse equipment0

-

Woodworking equipment0

Woodworking equipment0

-

Sandblasting equipment0

Sandblasting equipment0

-

Painting equipment0

Painting equipment0

-

Generators0

Generators0

-

Metal processing equipment0

Metal processing equipment0

- Laser cleaning equipment0

- Top Sheet metal forming machines0

- Industrial hydraulic presses0

- Metal sheet bending machines0

- Metal rolling machines0

- Sheet metal forming machines0

- Sheet metal guillotines0

- Metal grinding equipment0

- Pipe bending machines0

- Metal drilling machines0

- Metal lathes0

- Metal cutting machines0

- Metal milling machines0

- Metal dust extraction devices0

-

-282x282w.webp)

-282x282h.webp)

-282x282w.webp)