Wheel aligner geoliner® 790 AC400 Hofmann

- SKU: BD70458

27,799.00 €

Your shopping cart is empty!

Country of Origin: Italy, warranty period - 24 months

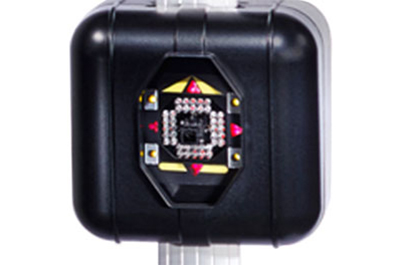

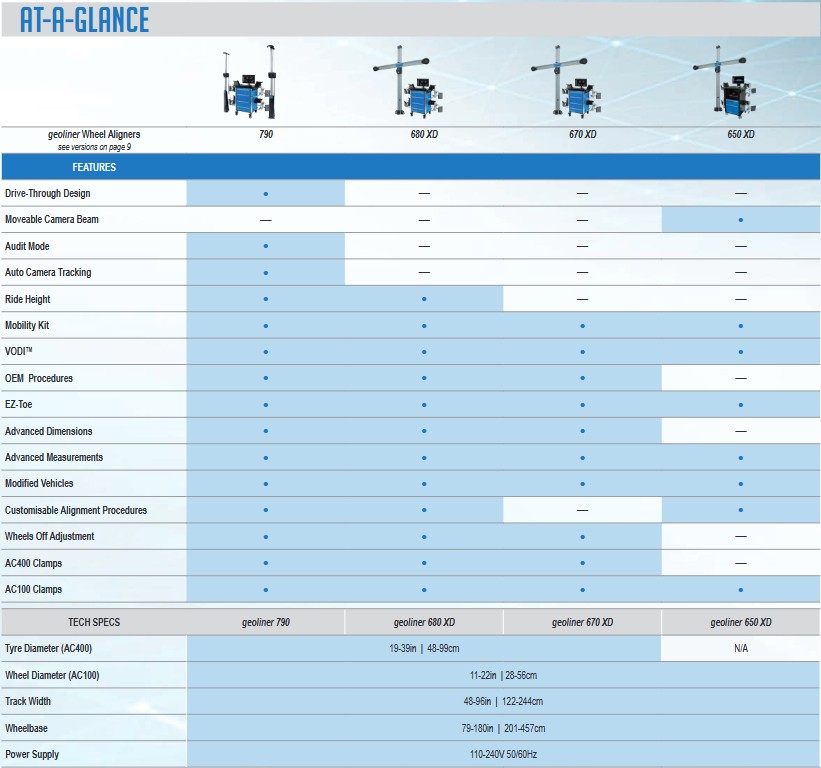

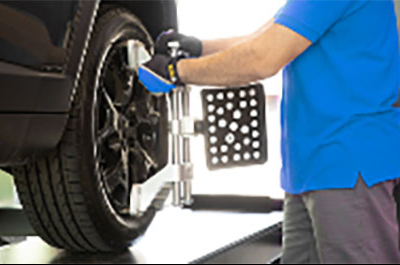

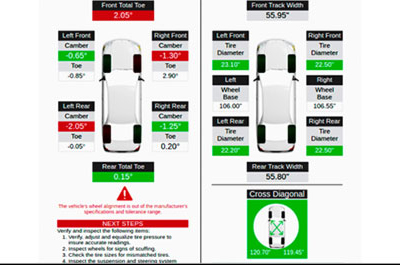

The geoliner® 790 AC400 is an advanced wireless 3-camera wheel aligner featuring XD technology, ideal for drive-through bays and high-efficiency service operations. This model offers flexible installation and usage across different service areas, while the integrated Pro42 PLATINUM software with icon-based interface provides all essential functions via a one-click system. The patented digital camera tracking system automatically adjusts to the vehicle height, allowing fast and precise target tracking. AC400 quick-release clamps ensure secure wheel attachment without contacting the rim, minimizing the risk of damage. An optional mobility kit allows easy relocation of the equipment between workstations.

![]()