Compliance with safety requirements in car services

We have prepared a list of recommendations to make car service employers and employees in these companies more compliant with safety and health requirements. Because car services deal with equipment that happens to cause various minor and severe accidents.

Employers need to be well aware of these requirements and pass on everything to the service mechanics who do the day-to-day work. Occupational risk assessments are often prepared for this.

Even during normal vehicle inspection and servicing, there are risks that can cause accidents. For example, even when changing oils, there is a risk of cancer. Because spent oil contains magnesium, zinc, copper and other heavy metals that damage the nervous system, kidneys or even can cause cancer, it is in contact with the used oil.

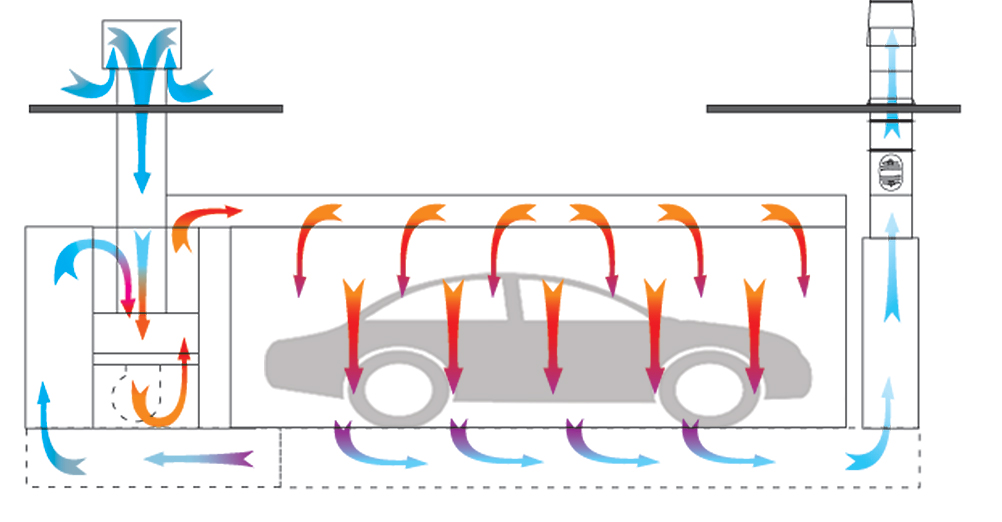

Often, mechanics must start the engine to check the operation of certain mechanisms. Because the gates are often closed at the service station, carbon dioxide builds up in the room. After some time, when the engines are started indoors, a cough is produced, followed by shortness of breath. Often working in such an environment, doctors and other health experts warn of an increased risk of developing lung cancer. Therefore, in order to avoid this, car service managers must always provide protective equipment or install exhaust extraction and filtration systems in the service area.

One of the most dangerous factors is when working underneath a forklift truck. These are some of the most common accidents when a raised vehicle falls on an employee. This is usually because the car is being lifted incorrectly or the handbrake has not been applied to the vehicle when it is raised on a four-pillar lift. However, there are often cases where the maintenance of the truck and improper equipment are not followed. For example, there is more lift than the truck than the manufacturer has set for maximum lift capacity. The dimensions of the car must also be taken into consideration. The manufacturers of lift trucks have solved the problem of a possible fall. They have built-in safety devices that are clearly marked, as well as built-in latches and lift height limiters.

It is strictly forbidden to use the truck in an unsuitable environment when working with car lifts; climbing on the chairlift itself or boarding a raised car; lifting people by lift; to stand under a lift for bystanders.

All lifts marketed in an EU country are CE marked, which is strict international standards. Such lifts must meet the following requirements: proper electrical installation in the lifts; protection of toes; there must be latches; specified maximum lifting capacity and other high standards.

Every car lift must be regularly serviced and inspected. It shall be carried out in accordance with the manufacturer's instructions, in the order and at the intervals specified. This is necessary to maximize the lifetime of the truck and to ensure that the truck is in good working order. If you want a quality inspection, it is best to contact us as our professional installers will do a quality inspection and write the necessary documents. Each hoist of the car has a technical passport and a mark is created. We recommend storing all this information while the truck is in service, which is one of the safety requirements at car services.

Often, service centers can still see car inspection pits that are still in widespread use. When this so called pit is in service, there is a danger not only to the pit worker but also to those around him. For example, when uncovered, workers may fall for them and suffer head injuries or other injuries. Therefore, it is recommended that if no one is working in this pit and no car is serviced - the pit should be kept covered.

Compressed air is used by car services to perform certain repairs. It is used in tire blasting, in tire mounting machines, paint sprayers, oil pumps, various pneumatic tools and more. Although these are rare accidents, they are usually caused by excessive compressed air accumulation in the equipment itself. To prevent this, it is necessary to ensure that all compressed air systems and associated equipment are constantly maintained.

Almost all modern cars have built-in air conditioning systems that are harmful to humans. The most common hazards of changing a refrigerant include: frostbite caused by skin contact; when the refrigerant gas enters the air there is the potential for suffocation or coughing and others.

To carry out a high-quality car air conditioner refill, you must have a good knowledge of the conditioner refill station. It is forbidden to discharge the refrigerant directly into the air when filling the car's air conditioning system. Do not carry out welding, brazing and welding near the explosion hazard. Mixing of different refrigerants, such as R12 with R134A, is prohibited. Do not overfill the air conditioning system with refrigerant. We also recommend you to follow many other safety requirements: use only quality equipment, implement preventive measures, dispose of refrigerants.

Respiratory diseases can often be contracted when working with bodywork and painting. Because they work with chemicals that are harmful to human health. Preventive measures in the workshops - Provide exhaust ventilation to remove all toxic chemicals.

The greatest danger is when working with paint mixing and application, since many thinners and paints emit flammable vapors. Therefore, such tanks must be tightly closed and stored in fire-resistant areas. The greatest risk when working with these tools is asthma. To avoid this, observe the following requirements: properly install paint chambers and other facilities; use respiratory protective equipment; conduct regular health care and examination.

Car mechanics risk their health every day when they go to work, more than a statistician, but all of this can certainly be avoided. We recommend following the instructions below:

- Always dispose of all waste in a timely manner;

- Do not overcharge car batteries, follow the manufacturer's recommendations;

- Discard and dispose of contaminated clothing and various cloths;

- Have gas extraction systems and recuperators installed;

- Use safe containers for liquids;

- Do not smoke in areas where gas is likely to accumulate;

- Keep the airbags in a safe and separate area;

- Keep liquids ready for disposal as small as possible;

- Continuous maintenance of equipment;

- It is forbidden to keep flammable gas and oxygen cylinders near.